High-Density Polyethylene (HDPE) sheets are a versatile and essential material used across industries for their durability, flexibility, and cost-effectiveness. From construction to packaging and agriculture, HDPE sheets provide reliable solutions for various applications. This article delves into the characteristics, benefits, and common uses of HDPE sheets, incorporating the keywords Hdpe plastic sheet, Plastic sheet hdpe, and Polyethylene sheet price to help you understand their significance and functionality.

What Are HDPE Sheets?

Excellent-Density Polyethylene, a thermoplastic polymer renowned for its excellent strength-to-density ratio, is used to make HDPE sheets. These sheets are lightweight, durable, and resistant to moisture, chemicals, and impact. Whether used in industrial settings or for everyday applications, HDPE sheets are a preferred material for their reliability and cost-effectiveness.

Key Features of HDPE Sheets

1. Exceptional Durability

HDPE sheets are highly resistant to wear and tear, making them suitable for environments exposed to heavy usage or harsh conditions.

2. Moisture and Chemical Resistance

Unlike other materials, HDPE plastic sheets resist water absorption and are unaffected by many chemicals, ensuring longevity in wet or chemically exposed settings.

3. UV Stability

UV-resistant grades of HDPE sheets are available for outdoor applications. These sheets retain their properties under prolonged sunlight exposure.

4. Lightweight and Flexible

HDPE sheets are lightweight and easy to handle and install despite their strength. Their flexibility allows them to adapt to various shapes and configurations.

5. Cost-Effectiveness

Compared to other materials like metals or glass, HDPE offers a cost-efficient solution without compromising on quality or performance.

Common Applications of HDPE Sheets

1. Construction Industry

HDPE sheets are widely used in construction for applications such as geomembranes, barriers, and concrete formwork. Their strength and resistance to chemicals make them ideal for these tasks.

2. Packaging Solutions

HDPE plastic sheets are used to manufacture containers, bottles, and other packaging materials. Their durability ensures safe storage and transportation of goods.

3. Agriculture

In agriculture, HDPE sheets are utilized for irrigation systems, greenhouse covers, and silos. Their resistance to weather conditions and chemicals ensures long-lasting performance.

4. Automotive Sector

The automotive industry uses Plastic sheet hdpe for parts like fuel tanks, bumpers, and interior panels. Their portability adds to their longevity and fuel efficiency.

5. Marine Applications

HDPE sheets are also used in docks, pontoons, and watercraft due to their excellent resistance to water and impact.

Benefits of HDPE Sheets

1. Environmental Friendliness

HDPE is an environmentally beneficial option for businesses looking for sustainable solutions because it is 100% recyclable.

2. Customizability

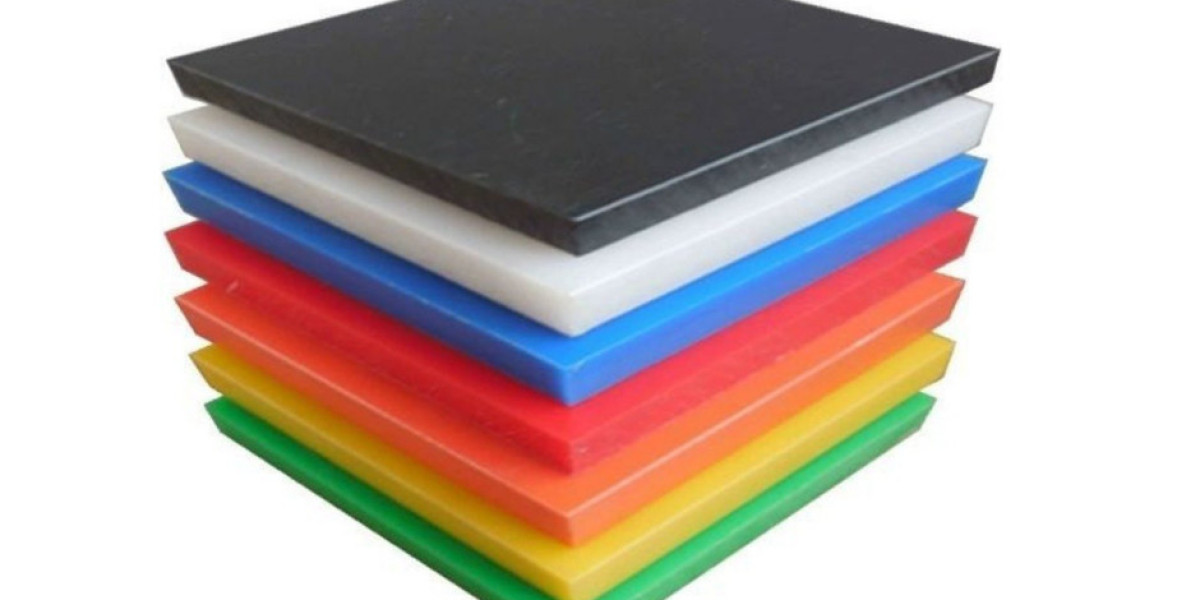

HDPE sheets are available in various thicknesses, sizes, and colors, catering to diverse industrial and commercial needs.

3. High Impact Resistance

Even under heavy loads or impacts, HDPE sheets maintain their structural integrity, ensuring safety and durability.

4. Temperature Tolerance

HDPE can withstand a wide temperature range, making it suitable for both hot and cold environments.

5. Low Maintenance

The smooth surface of HDPE sheets resists dirt and stains, reducing the need for frequent cleaning or repairs.

How to Choose the Right HDPE Sheet

1. Identify Your Requirements

Understanding your application will help you determine the required thickness, size, and grade of HDPE sheet.

2. Compare Polyethylene Sheet Prices

The Polyethylene sheet price can vary depending on thickness, quality, and supplier. To find the best bargain, compare prices from reliable vendors.

3. Check for UV Resistance

For outdoor applications, opt for UV-stabilized HDPE sheets to ensure long-term durability.

4. Consider Environmental Impact

Choose HDPE sheets that are recyclable and eco-friendly to align with sustainable practices.

5. Verify Supplier Credentials

Always source HDPE sheets from reliable suppliers with a proven track record for quality and consistency.

Maintenance Tips for HDPE Sheets

- Frequent Cleaning: To preserve the look and performance of HDPE sheets, clean them with a moderate soap and water solution.

- Avoid Abrasive Tools: When cleaning or handling, avoid using abrasive tools that could scratch the surface.

- Store Properly: Keep HDPE sheets in a dry, cool place to prevent warping or damage during storage.

- Inspect Regularly: Periodically check for cracks, warping, or other signs of wear, especially in high-stress applications.

Conclusion

HDPE sheets have become a cornerstone material in industries ranging from construction to packaging due to their unmatched combination of durability, flexibility, and cost-effectiveness. Whether you're looking for hdpe plastic sheet solutions for industrial applications or considering Plastic sheet hdpe for outdoor projects, these versatile sheets are an excellent investment.

By understanding your needs and exploring various options, you can find the right HDPE sheet that fits your project requirements and budget. Reliable suppliers and proper maintenance further enhance the value and performance of this indispensable material.

Frequently Asked Questions (FAQs)

1. What is the typical lifespan of HDPE sheets?

HDPE sheets can last for decades, depending on their application and exposure to environmental factors. Proper maintenance and using UV-resistant grades can extend their lifespan further.

2. Are HDPE sheets safe for food-related applications?

Yes, food-grade HDPE sheets are widely used in the food industry for cutting boards, storage containers, and other applications. They are FDA-approved, non-toxic, and simple to clean.

3. How can I determine the cost of HDPE sheets?

The Polyethylene sheet price depends on factors like size, thickness, grade, and supplier. It's advisable to get quotes from multiple suppliers and consider shipping costs when calculating the overall expense.