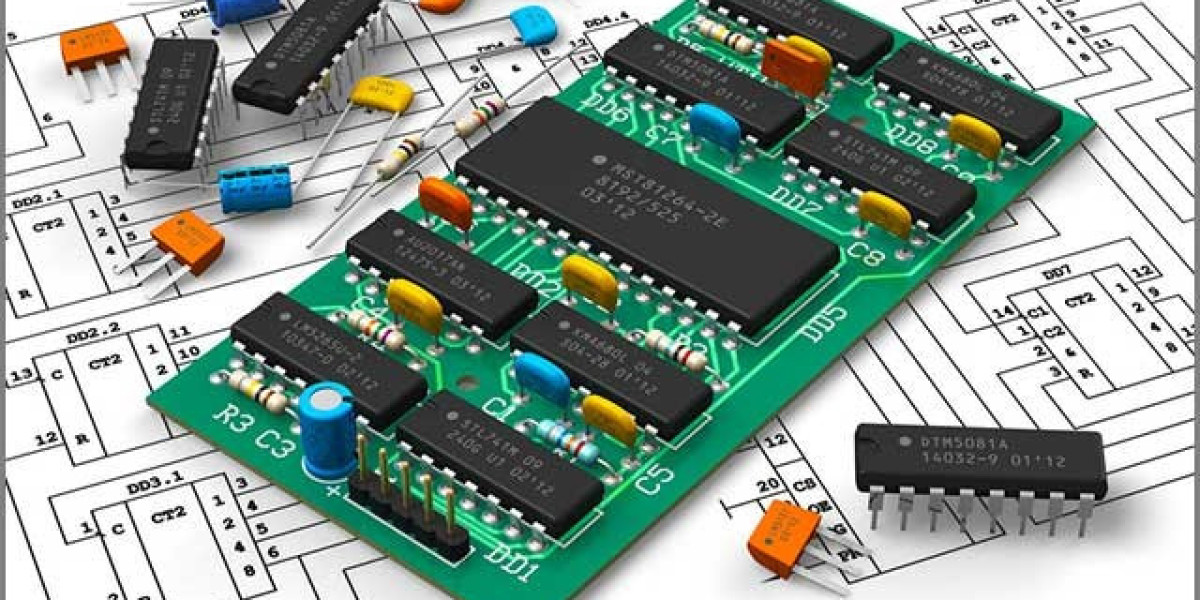

One of the most important steps when making electronic devices is the design of the electronic layout. This process is crucial for ensuring the device works properly and is reliable. A good layout can improve how the device performs, how long it lasts, and how much it costs. It also helps to avoid problems like overheating or losing power. In this article, we’ll look at how electronics layout design works and why it’s important for building better devices.

Why Electronics Layout Design is Important

In electronics, every part of a device must be placed carefully. This includes things like microchips, wires, and other components. The device might not work correctly or break easily if the layout is poorly done. A good design will ensure electricity flows smoothly through the device, reducing the risk of damage.

Having a good layout also helps to make the manufacturing process faster and less expensive. If the design is done well, manufacturers can avoid problems later, saving time and money. By getting the design right, the final product will be more reliable, which benefits both the manufacturer and the customer.

Key Parts of Electronics Layout Design

Signal Integrity

Signal integrity means that the electrical signals in the device are clear and strong. If the signals are weak or distorted, the device might not work as expected. In the layout, the paths for these signals must be as short and direct as possible to avoid any problems. A good design will help keep signals strong and clear.

Power Distribution

Power distribution means ensuring the device gets the right amount of power where it’s needed. The device might overheat or stop working if the power isn’t distributed correctly. A good layout will make sure the power is delivered in a way that keeps the device running smoothly.

Thermal Management

All electronic devices generate heat while they work. If this heat isn’t managed correctly, it can cause the device to fail. Designers use tools like heat sinks to help remove the heat in the layout. A good design will remove heat quickly, keeping the device safe and working well.

Electromagnetic Compatibility (EMC)

Electromagnetic interference (EMI) happens when a device causes or is affected by unwanted electrical noise. This can lead to the device not working as it should. A good layout will help make sure the device works properly and doesn’t interfere with other devices. It also ensures the device is not affected by interference from different sources.

Benefits of Good Layout Design

Good electronics layout design has many benefits for manufacturers. For one, it helps ensure the device works correctly and has fewer problems. This helps reduce costs because there are fewer mistakes to fix during production.

A well-designed layout also means the device will likely work better and last longer. This makes customers happier and more likely to trust the brand. With the right design, a product can meet customer needs while being cost-effective.

Another benefit of good layout design is that it makes testing and repairing devices easier. When the layout is done correctly, manufacturers can quickly spot and fix problems. This saves time and reduces costs for the company.

How Product Design Services Help with Layout

Product design services play a significant role in creating a good layout. Designers use special software to plan out the layout before building a prototype. This lets them test the design and make changes if needed. By using the best design practices, manufacturers can create better devices faster.

With innovative manufacturing services, companies can use automated systems to build devices with high precision. This helps to reduce errors and ensures the final product meets high standards.

Conclusion

In short, designing electronics layouts is crucial for building suitable devices. It helps improve performance, reduce costs, and ensure devices last longer. By focusing on key areas like signal integrity, power distribution, thermal management, and electromagnetic compatibility, manufacturers can create better products that work well for customers. As design tools and manufacturing processes improve, the future of electronic device production looks even brighter.