Unveiling T-Type Strainers

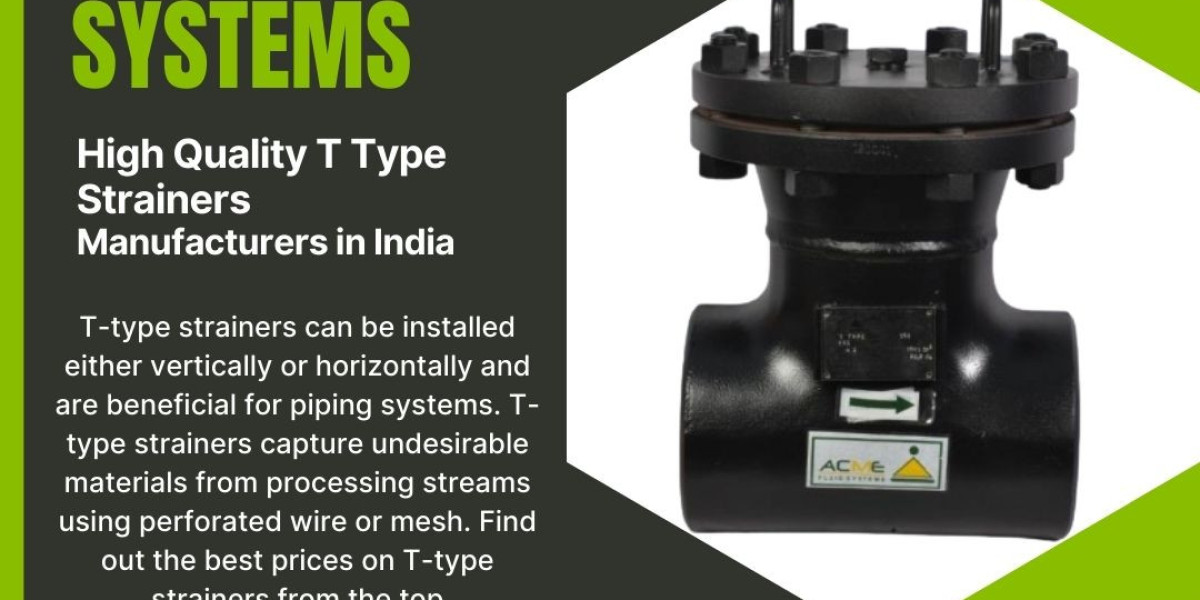

T-Type strainers are compact filtration apparatuses engineered to extricate solid impurities from fluid or gas conduits. Distinct from alternatives like Y-Type or Basket strainers, their unique configuration epitomizes efficiency paired with adaptability.

Core Constituents of T-Type Strainers

The architecture of T Type strainers encompasses the following pivotal elements:

- Casing Material: Crafted from robust materials such as stainless steel or cast iron, ensuring endurance.

- Filtration Mesh: Precision-engineered screens that dictate filtration efficacy.

- Access Cover: Designed for effortless maintenance and cleaning procedures.

Operational Mechanics of T-Type Strainers

These strainers function through enforced filtration principles, channeling process fluids through a meticulously designed mesh that ensnares impurities. The streamlined flow dynamics mitigate pressure drops, thereby bolstering operational efficiency.

Industrial Utilization of T-Type Strainers

T-Type strainers find utility across a spectrum of sectors:

- Petrochemical Sector: Upholding the purity of processing fluids.

- Chemical Industry: Safe filtration of corrosive substances.

- Water Purification: Extraction of debris from water pipelines.

- Food & Beverage Sector: Guaranteeing hygienic fluid transport.

- Energy Generation: Shielding turbines and cooling frameworks from contaminants.

Merits of T-Type Strainers

- Enhanced Efficiency: Effectively captures impurities while maintaining minimal pressure diminution.

- Robust Durability: Engineered to endure challenging industrial settings.

- Economic Viability: Curtails downtime and trims maintenance expenditures.

Material Varieties in T-Type Strainers

Material selection is pivotal for performance:

- Stainless Steel: Optimal for high-temperature or corrosive applications.

- Cast Iron: A budget-friendly choice for general use cases.

- Polymers: Lightweight and resistant to corrosion for niche requirements.

Factors Influencing Strainer Selection

Consider these critical parameters:

- Dimensional Compatibility: Ensuring the strainer aligns with system flow dynamics.

- Material Suitability: Tailoring material to the fluid's chemical properties.

Maintenance Strategies for Longevity

Routine assessments and cleaning are imperative to prolong service life. Employ manual or automated methodologies to expunge debris and replace worn components as necessary.

Financial Prudence of T-Type Strainers

Opting for high-quality strainers mitigates costs associated with equipment failures and reduces energy demands, proving a sound investment.

Navigating Challenges

Obstacles like clogging are counteracted through systematic cleaning, while judicious material selection precludes incompatibilities.

Sustainability Contributions

By diminishing waste and optimizing resource use, T-Type strainers bolster environmental stewardship.

Innovations in T-Type Strainer Technology

Modern advancements feature self-cleansing capabilities and IoT integrations, enabling real-time performance monitoring.

Adherence to Standards

Compliance with industry benchmarks such as ISO and ASME ensures that T-Type strainers operate with safety and efficiency.

Frequently Asked Questions

- What is the function of T-Type strainers?

They filter impurities from industrial pipeline fluids. - How often should they undergo cleaning?

Cleaning frequency varies but typically spans weekly to monthly intervals. - Which materials suit corrosive environments?

Stainless steel excels in handling corrosive conditions. - Can these strainers endure high-pressure systems?

Yes, they are robustly designed for significant pressure thresholds. - Which industries depend on them?

Sectors such as petrochemicals, water treatment, and food processing rely heavily on their efficacy. - How to determine the right size?

Consult manufacturer guidelines to match system specifications accurately.

Conclusion

T-Type strainers are quintessential to industrial functionality, offering unparalleled filtration and ensuring system resilience. Their versatility, durability, and economic advantages underscore their vital role across global industries.