In today’s fast-paced manufacturing environment, precision, speed, and flexibility are paramount. Lumitool lasermarking offers all these attributes and more, making it a leading choice for businesses looking to elevate their marking and engraving processes. As an industry leader in advanced laser technology, Lumitool has created a range of innovative solutions designed to meet the diverse needs of industries such as aerospace, automotive, electronics, and consumer goods. In this article, we’ll explore the features, benefits, applications, and future potential of Lumitool laser marking machines.

Key Features of Lumitool Laser Marking Machines

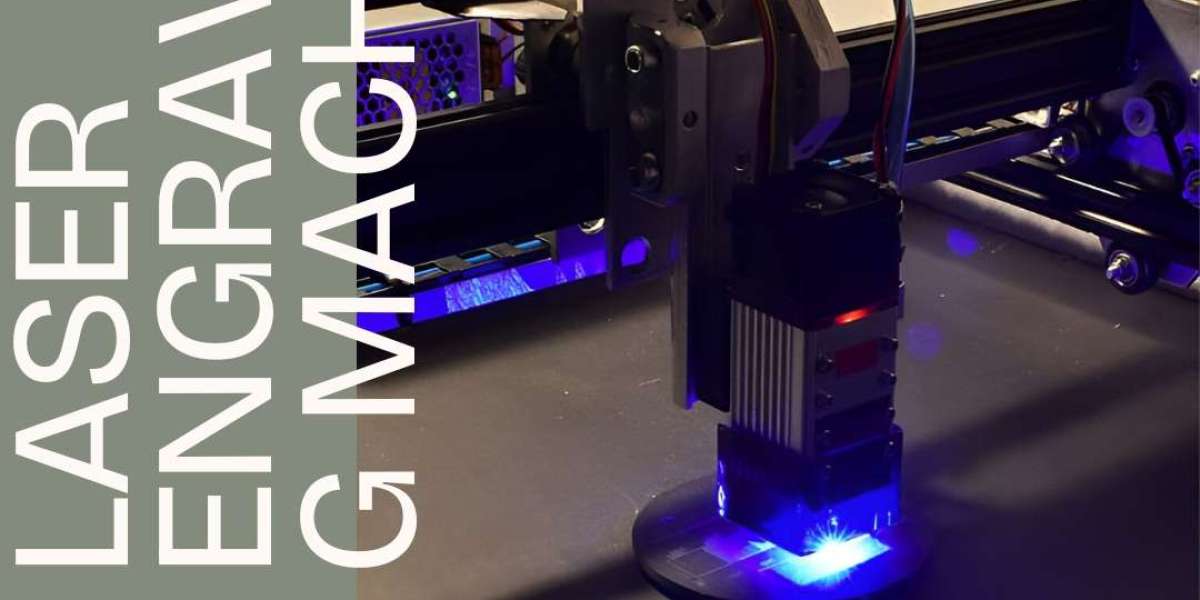

Lumitool’s laser marking technology stands out due to its high-powered fiber laser systems, which provide unparalleled precision and efficiency. These machines utilize advanced laser sources that focus light into a fine beam, allowing for exceptionally detailed markings on a wide variety of materials. Whether it’s engraving metals, plastics, ceramics, or even some organic materials, Lumitool machines offer remarkable flexibility.

One of the defining features of Lumitool laser marking machines is their speed and accuracy. With cutting-edge technology, these machines can achieve incredibly fast processing times without compromising on the quality of the marking. The high energy density and rapid pulse frequency of the lasers allow for high throughput, making it suitable for high-volume production lines that require consistent, high-quality markings.

Furthermore, Lumitool laser marking machines are designed with user-friendliness in mind. The intuitive software interface simplifies the engraving process, enabling operators to program designs with ease, ensuring smooth operation even for users with minimal experience. Additionally, the machines are engineered to minimize maintenance needs, reducing downtime and ensuring continuous productivity.

Benefits of Lumitool Laser Marking

1. Precision and Detail: One of the biggest advantages of using Lumitool laser marking machines is the exceptional precision they provide. The lasers can be finely controlled to create intricate designs, logos, text, barcodes, and more with high clarity and sharpness. Whether it’s marking small parts with tiny characters or large surfaces with intricate patterns, Lumitool’s technology delivers consistent results every time.

2. Durability of Marks: The marks created using Lumitool lasers are permanent and highly resistant to fading, scratching, or wear over time. This is especially important in industries like aerospace and automotive, where identification marks need to withstand harsh environmental conditions without losing their clarity. The laser marking process ensures that the markings remain legible for the lifetime of the product, even under challenging circumstances.

3. Versatility: Lumitool laser marking machines can handle a variety of materials, from metals like stainless steel, aluminum, and titanium to plastics, ceramics, and even glass. This versatility makes them ideal for industries that require customization or a wide range of materials to be processed. Whether for branding, traceability, or product identification, Lumitool’s machines are capable of handling virtually any engraving task with ease.

4. Eco-friendly: As a non-contact, non-consumable process, laser marking eliminates the need for toxic chemicals, inks, or paints. This not only makes it more environmentally friendly compared to traditional methods but also reduces waste and the potential for harmful emissions. Lumitool laser marking is thus an excellent choice for companies looking to minimize their environmental impact while maintaining high standards of quality.

5. Low Maintenance: Since Lumitool laser marking machines use no consumables like ink or glue, they have fewer parts that need replacing. This significantly reduces maintenance costs and downtime. The systems are designed to be robust, and the laser source itself can last for a long time, making it a cost-effective investment in the long run.

Applications of Lumitool Laser Marking

Lumitool laser marking machines find applications across a broad spectrum of industries due to their precision, speed, and flexibility. Below are some key areas where Lumitool’s technology excels:

Automotive Industry: In the automotive sector, Lumitool laser marking machines are used to mark vital components such as serial numbers, VIN numbers, and part identification marks. The permanent, durable markings ensure that parts can be easily traced, which is crucial for quality control, safety compliance, and regulatory requirements.

Aerospace: Aerospace manufacturers rely on Lumitool’s precision to engrave identification marks, part numbers, and safety information on aircraft components. Given the harsh conditions under which aerospace parts must perform, the durability and legibility of laser markings are crucial for safety and traceability.

Electronics: In the electronics industry, where small components are often used, Lumitool laser marking machines are ideal for creating clear, concise, and permanent markings such as serial numbers, logos, and barcodes on circuit boards, connectors, and other sensitive components.

Medical Devices: Precision is paramount in the medical field, and Lumitool laser marking technology offers the accuracy required for marking medical devices, implants, and surgical instruments. The high durability of the marks ensures they remain readable throughout the lifespan of these critical products.

Jewelry: Lumitool’s technology is also used to create intricate designs and markings on jewelry pieces. From engraving logos to adding custom text or designs, Lumitool laser marking machines provide the precision needed for fine jewelry manufacturers.

Consumer Goods: Lumitool machines are widely used in the consumer goods sector for branding and customization. Whether marking luxury items, electronics, or everyday products, these machines offer high-quality, permanent markings that enhance the consumer experience.

The Future of Lumitool Laser Marking

The future of Lumitool laser marking technology looks promising, with advancements continually pushing the boundaries of what these machines can achieve. The integration of automation and artificial intelligence (AI) into laser marking processes is one area that holds great potential. Automation will allow for even higher throughput, while AI could optimize engraving patterns, improving efficiency and reducing the risk of errors.

Another exciting development is the potential for 3D laser marking. This would enable more complex and detailed engraving on a wider variety of surfaces, opening new possibilities for industries such as aerospace and medical devices, where intricate, three-dimensional designs are increasingly in demand.

As industries evolve, Lumitool’s laser marking machines will continue to be at the forefront of innovation, offering businesses the tools they need to meet the demands of modern manufacturing.

Conclusion

Lumitool Laser Marking offers businesses a powerful, precise, and efficient solution for all their engraving needs. With high-speed processing, unparalleled precision, and minimal maintenance, Lumitool’s technology is revolutionizing industries around the world. Whether for product identification, traceability, or intricate design, Lumitool laser marking machines are setting new standards in the field, helping businesses maintain quality, sustainability, and innovation.