Introduction: Crafting Quality Dental Prosthetics

Dental laboratory welders are essential tools in the fabrication of high-quality dental prosthetics, such as bridges, crowns, and orthodontic appliances. These devices provide precise and durable welds, ensuring the structural integrity and longevity of dental restorations. The dental laboratory welders market is focused on providing reliable and efficient welding solutions for dental technicians.

Mechanisms of Action: Joining Metal Components with Precision

Dental laboratory welders use various welding techniques, such as laser welding, resistance welding, and TIG welding, to join metal components. These techniques involve applying heat and pressure to create a strong and seamless bond between metal parts. The precision of these welds is paramount for proper fitting prosthetics.

Applications in Dental Prosthetics Fabrication: Ensuring Structural Integrity

Dental laboratory welders are used in the fabrication of various dental prosthetics, including fixed partial dentures, metal-ceramic crowns, and orthodontic appliances. These devices ensure the structural integrity and durability of dental restorations, providing patients with reliable and long-lasting solutions.

Laser Welding: High Precision and Minimal Heat Transfer

Laser welding is a popular technique in dental laboratories due to its high precision and minimal heat transfer. This technique uses a focused laser beam to create a precise weld, minimizing the risk of distortion and damage to surrounding materials. Laser welders are ideal for intricate and delicate welding tasks.

Resistance Welding: Efficient and Cost-Effective Joining

Resistance welding is an efficient and cost-effective technique used for joining metal components in dental prosthetics. This technique involves passing an electric current through the metal parts, creating a localized heat that fuses them together. Resistance welders are suitable for high-volume production and repetitive welding tasks.

Tungsten Inert Gas (TIG) Welding: Versatility and High-Quality Welds

TIG welding is a versatile technique that provides high-quality welds in dental prosthetics. This technique uses a tungsten electrode to create an arc that melts the metal components, while an inert gas shield protects the weld from contamination. TIG welders are suitable for a wide range of metal alloys and welding applications.

Digital Integration and Automation: Enhancing Workflow Efficiency

Digital integration and automation are enhancing workflow efficiency in dental laboratories. This includes the integration of CAD/CAM systems with dental laboratory welders, enabling precise and automated welding processes. Automated welders improve consistency and reduce manual errors.

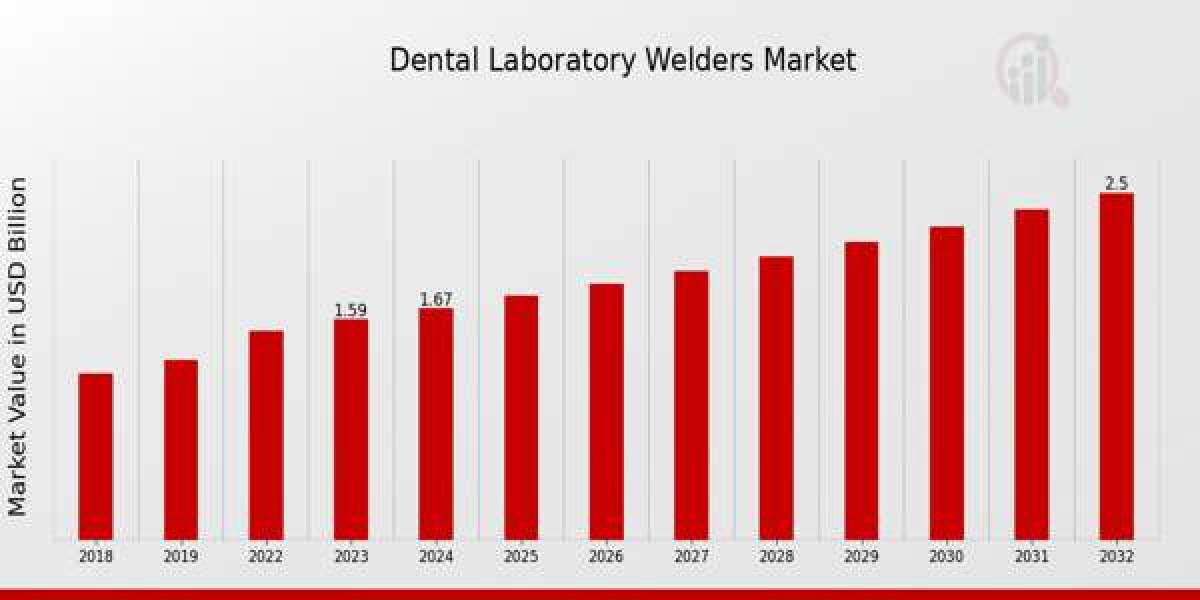

Dental Laboratory Welders Market Overview

As per MRFR analysis, the Dental Laboratory Welders Market Size was estimated at 1.76 (USD Billion) in 2024. The Dental Laboratory Welders Market Industry is expected to grow from 1.85 (USD Billion) in 2025 to 2.90 (USD Billion) till 2034, at a CAGR (growth rate) is expected to be around 5.16% during the forecast period (2025 - 2034).

Ergonomics and Safety: Ensuring Technician Comfort and Protection

Ergonomics and safety are crucial considerations in the design of dental laboratory welders. This includes features such as adjustable workstations, ergonomic handles, and safety shields. These features aim to ensure technician comfort, reduce fatigue, and minimize the risk of injury.

Future Directions and Research: Advancements in Welding Technology

Research and development efforts are focused on advancing welding technology in dental laboratories. This includes the development of new welding techniques, improved welding materials, and integrated quality control systems. These advancements aim to further enhance the precision, durability, and efficiency of dental prosthetics fabrication.

Conclusion: Essential Tools for Quality Dental Restorations

Dental laboratory welders are essential tools in the fabrication of high-quality dental prosthetics. By providing precise and durable welds, these devices ensure the structural integrity and longevity of dental restorations. As technology continues to advance, we can expect to see even more innovative welding solutions in dental laboratories, improving patient outcomes and enhancing the quality of dental care.

Explore Our Latest Reports

? Respiratory Infectious Disease Diagnostics Market

? Healthcare Provider Network Management Market

? Androgenetic Alopecia Market

? Sugar Based Excipients Market

? Stay ahead in the healthcare industry. Browse our latest insights now!

About Market Research Future (MRFR)

Market Research Future (MRFR) is a global market research firm that provides comprehensive insights into market trends, drivers, challenges, and opportunities. We offer a broad range of market intelligence reports and consulting services to help businesses and enterprises in various industries make informed decisions

Media Contact:

Market Research Future (MRFR)

Phone: +1-646-845-9312

Email: contact@marketresearchfuture.com

Website: marketresearchfuture