Having an industrial 3d printer is a great thing, but what about the rest of the environment that keeps the production of strong, accurate, and high-quality parts consistently? Such an environment is frequently encountered in the industry with temperature fluctuations, dust, noise, and vibration. Such protection must be afforded to the even advanced printer from faltering. So, there is a need for an enclosure that has high specifications and design for insulation, noise control, air flow regulation, and print stability in general.

Importance of Quality Enclosure in Professional Setups

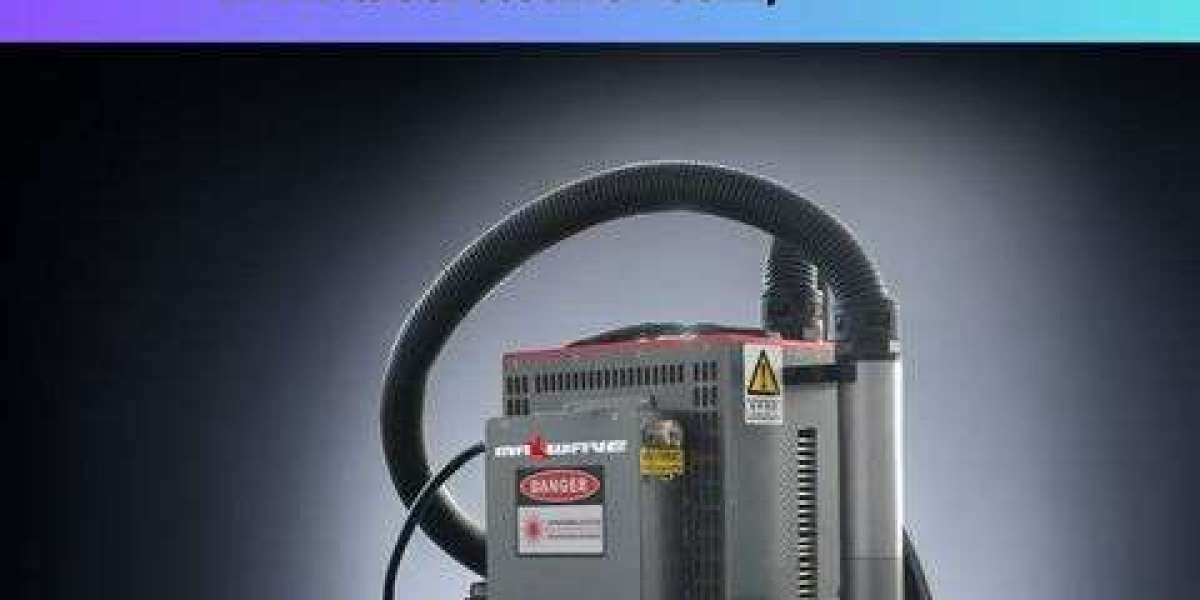

A Delack Storage Cabinet is far more than just a basic container for your 3D printer—it’s a precision-engineered solution for creating a stable, controlled workspace. Designed to maintain optimal operating temperatures, shield sensitive components from dust and debris, and enhance workplace safety, this heavy-duty enclosure is ideal for professionals printing large or technical parts. By preventing warping, cracking, and print failures, a Delack Storage Cabinet ensures consistent results while protecting your investment.

Designed for Tough Environments

Unlike basic desktop enclosures, the Delack enclosure is designed for industrial applications. It comprises rugged and robust materials suitable for the rigors of factory floors, workshops, and high-production bulk areas. This enclosure withstands dust, movement, and high heat. Its heavy-duty frame and panels are designed for longevity, making it a good investment for anyone in professional manufacturing.

Temperature Control at Its Finest

Consistent temperature is one of the glue points for effective 3d printing. It is especially key when working with advanced materials: ABS, Nylon, or Polycarbonate. The design of Delack is able to trap the internal heat content and keep the whole 3d printer warm, even at the temperature surrounding the print. This reduces the chances of thermal contraction and secures layer adhesion from the bottom layer all the way to the top. Certain models even allow heating up, so printing can occur with materials that would otherwise warp without support.

Minimizing Noise and Vibration

3D printers, especially industrial ones, can be noisy. In a shared workspace or office, this can be disruptive. The enclosure acts as sound insulation and, to a large degree, can reduce machine noise to provide a quieter yet more comfortable working environment. Another important benefit of enclosure is vibration damping, which in turn minimizes potential imperfections in the printed model. This is critical for high-precision parts, where even the slightest error can throw off the entire result.

Enhanced Safety Features

This is because safety is always a big issue, especially in commercial or industrial settings. Safety features such as enclosures are installed to protect machines and users. Others include fireproof stuff, door locks, and air vents for dealing with the fumes produced from heating filaments securely. On the other hand, when machines are running for hours or days, these protective measures allow a feeling that one is safer and more secure in the work space. Finally, the temperature sensors are integrated, and automatic shut-off mechanisms are available to offer additional protection to both equipment and personnel under extended operation.

Streamlining Maintenance and Workflows

Another important benefit of heavy-duty enclosures is easy organization and maintenance. They prevent dust and debris from entering the moving parts and causing heavy wear, making maintenance easier because your printer stays cleaner and more protected. Some setups even allow for installing tools, spools, or monitoring equipment directly on or inside the enclosure for a more organized workflow.

Designed For Professionals

A solid setup is non-negotiable for running a print farm, prototyping parts for clients, or economically producing functional parts of the end-use type. This was the very purpose the Delack enclosure was designed to serve. It doesn't just provide protection—the Delack enclosure actively enhances the quality and consistency of every print. With industrial-grade features, it becomes an essential tool in an organization that bases its operations on high-performance printing. There is one more feature in it that it has a Prusa mini silicon sock that helps in smooth process and free of error activities.

A Worthwhile Investment for Long-Term Productivity

For companies preparing to scale up or improve production, upgrading the environment surrounding your printer is as important as adjusting the printer itself. The price of a rugged enclosure may seem high at first, but long-term savings concerning failed prints, upkeep, and downtime justify the expense. It's not about spending more; it's about protecting your equipment while maximizing every print hour.

Conclusion

Time is the currency in the industrial world of 3D printing. Reliability and precision are everything. For the professional who is looking for more, the Delack enclosure presents an extremely impressive solution. This will improve awareness of heat, keep dirt out, diminish noise, add to safety, and, in general, enhance printing quality and efficiency. It is designed with reinforced panels with modular components and continuous printing support to reduce downtime. This is the missing link for your setup and heavy-duty enclosure if you are looking for perfection in a demanding environment.