Dry Ice Blasting: A Clean and Modern Solution for Industrial Cleaning

In modern industrial and commercial environments, keeping equipment clean is essential for maintaining efficiency and safety. Traditional cleaning methods such as sandblasting, pressure washing, or using chemical solvents often pose risks to both the equipment and the environment. In contrast, dry ice blasting offers a safer and cleaner alternative that is gaining popularity across a wide range of industries.

What Is Dry Ice Blasting?

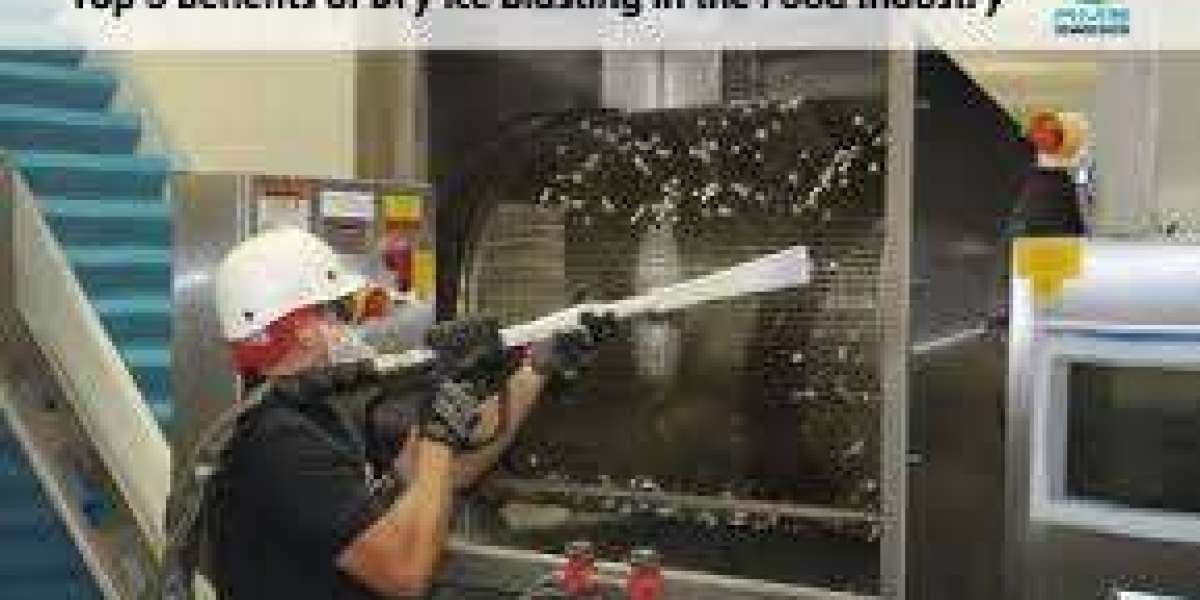

Dry ice blasting is a cleaning process that uses compressed air to propel dry ice pellets at high speed toward a surface. Dry ice is the solid form of carbon dioxide (CO₂), and it sublimates directly into gas upon impact. This means it turns from a solid into a gas without leaving any liquid or solid residue behind.

When the pellets hit a dirty surface, they rapidly cool and crack the bond between the surface and the contaminant. The impact and sudden temperature drop cause the dirt or unwanted material to loosen and detach. Since the dry ice evaporates immediately after doing its job, the cleaning process leaves no secondary waste to clean up, making it much more efficient.

Advantages Over Traditional Methods

One of the most important benefits of dry ice blasting is its non-abrasive nature. Unlike sandblasting or wire brushing, it does not wear down or damage the surfaces being cleaned. This makes it especially valuable for cleaning sensitive equipment or surfaces that must remain intact, such as electrical components, delicate machinery, or painted surfaces.

The method is also completely dry. Since no water or chemicals are involved, there is no risk of moisture damage, corrosion, or chemical contamination. This makes dry ice blasting particularly useful in environments where water or solvent-based cleaning is not practical, such as food processing plants, power facilities, or areas with electronic systems.

Applications Across Industries

Dry ice blasting is used in a wide variety of settings. In the food and beverage industry, it helps clean production lines, ovens, mixers, and conveyors without introducing moisture or chemical residues. It is an effective solution for maintaining hygiene without halting production for long periods.

In the automotive and aerospace sectors, it is used to remove grease, oils, adhesives, and even paint from parts without damaging the surface. Factories and manufacturing plants use it to clean equipment, molds, and machinery that would be difficult or time-consuming to disassemble.

It is also widely used for cleaning electrical components like generators, turbines, and switchboards, especially when it is not possible to shut down operations. The process does not conduct electricity, so it can often be done without powering down.

In the field of building restoration, dry ice blasting is a useful method for removing soot, mold, or old paint from bricks, wood, and stone without affecting the structural integrity or appearance of the surface.

Things to Consider

Despite its many advantages, dry ice blasting does come with some limitations. The initial cost of purchasing or renting equipment can be high, and trained operators are necessary to handle the machinery safely and effectively. It also requires access to a steady supply of dry ice, which needs to be stored properly to prevent it from evaporating too quickly.

Another consideration is the noise level. The blasting process can be quite loud, so protective gear such as earplugs is often required during operation. The rapid release of carbon dioxide gas also makes proper ventilation essential, especially in enclosed spaces, to avoid buildup that could displace oxygen.

Safety and Environmental Impact

Dry ice blasting is widely considered a safe and environmentally friendly cleaning method. Since it does not use chemicals, it reduces the risk of harmful exposure for workers and eliminates the need for hazardous waste disposal. The carbon dioxide used is often a byproduct of other industrial processes, so it does not add new emissions into the atmosphere.

Safety protocols include wearing protective clothing, gloves, and eye protection, and ensuring good airflow in the work area. With proper precautions, the method is safe for both operators and the environment.

Conclusion

Dry ice blasting is a modern, efficient, and environmentally responsible way to clean equipment and surfaces across a wide range of industries. Its ability to clean without damaging materials or leaving residue makes it a valuable tool in today’s world, where safety, sustainability, and productivity are more important than ever.

Though it may require a larger initial investment and some safety considerations, the long-term benefits—such as reduced downtime, improved cleanliness, and environmental compliance—make dry ice blasting a smart choice for many businesses seeking better cleaning solutions.