The Limit State Method (LSM) of design is a modern approach to structural design, including for steel structures, which ensures both safety and serviceability. This method has replaced older methods like the Working Stress Method (WSM) in many standards, as it provides a more realistic assessment of strength and performance. Here's a detailed overview of the LSM in the context of steel structures:

Key Concepts of the Limit State Method

Limit States:

- Ultimate Limit State (ULS): Ensures that the structure remains safe under maximum loads without collapse. It considers strength, stability, and overall structural integrity.

- Serviceability Limit State (SLS): Ensures that the structure performs well under normal usage without excessive deflections, vibrations, or cracking.

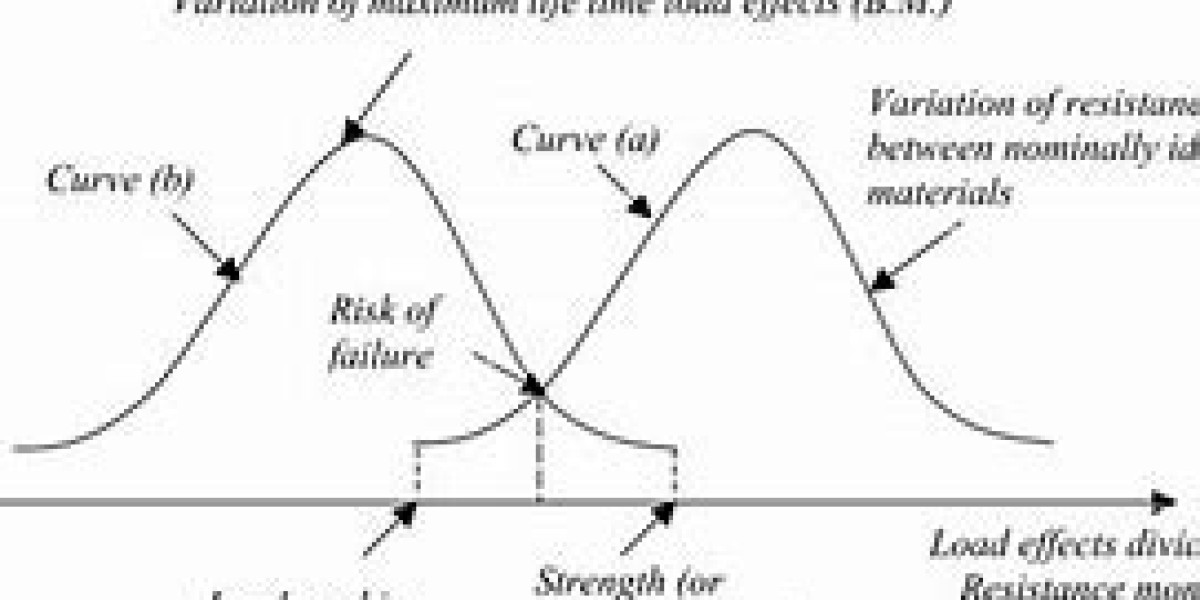

Partial Safety Factors:

- Separate safety factors are applied to loads and material strengths to account for uncertainties in loading conditions and material behavior.

Load Combinations:

- Different types of loads (dead load, live load, wind load, etc.) are combined using specified factors to represent critical conditions.

Advantages of LSM for Steel Structures

- Provides a more accurate and economical design compared to WSM.

- Considers both ultimate strength and serviceability, balancing safety and usability.

- Allows for the use of advanced materials and construction techniques.

Steps in Limit State Design for Steel Structures

Identify Design Loads:

- Determine the loads acting on the structure, including dead loads, live loads, wind loads, seismic loads, and other relevant forces.

Apply Load Combinations:

- Combine loads as per the relevant design code (e.g., IS 800 in India, Eurocode 3 in Europe, or AISC in the US).

Check for Ultimate Limit State:

- Ensure that the design strength of steel members exceeds the factored loads using partial safety factors.

Check for Serviceability Limit State:

- Verify that deformations, deflections, and vibrations remain within permissible limits under service loads.

Design Connections:

- Design joints and connections (bolted or welded) to withstand the loads and ensure overall stability.

Detailing and Documentation:

- Prepare detailed drawings and specifications for construction.

Limit State Design Checks

Tension Members:

- Verify against yielding, rupture, and block shear.

Compression Members:

- Check for buckling (flexural, torsional, or flexural-torsional buckling).

Flexural Members:

- Ensure sufficient bending strength and check for lateral-torsional buckling.

Combined Stresses:

- Account for combined effects of bending, shear, and axial loads.

Deflection Control:

- Verify that deflections do not exceed specified limits for serviceability.

Codal Provisions

- IS 800: 2007 (India): LSM is the recommended design approach for steel structures.

- Eurocode 3 (Europe): Specifies LSM as the standard method for structural steel design.

- AISC LRFD (US): Uses Load and Resistance Factor Design (LRFD), equivalent to LSM.