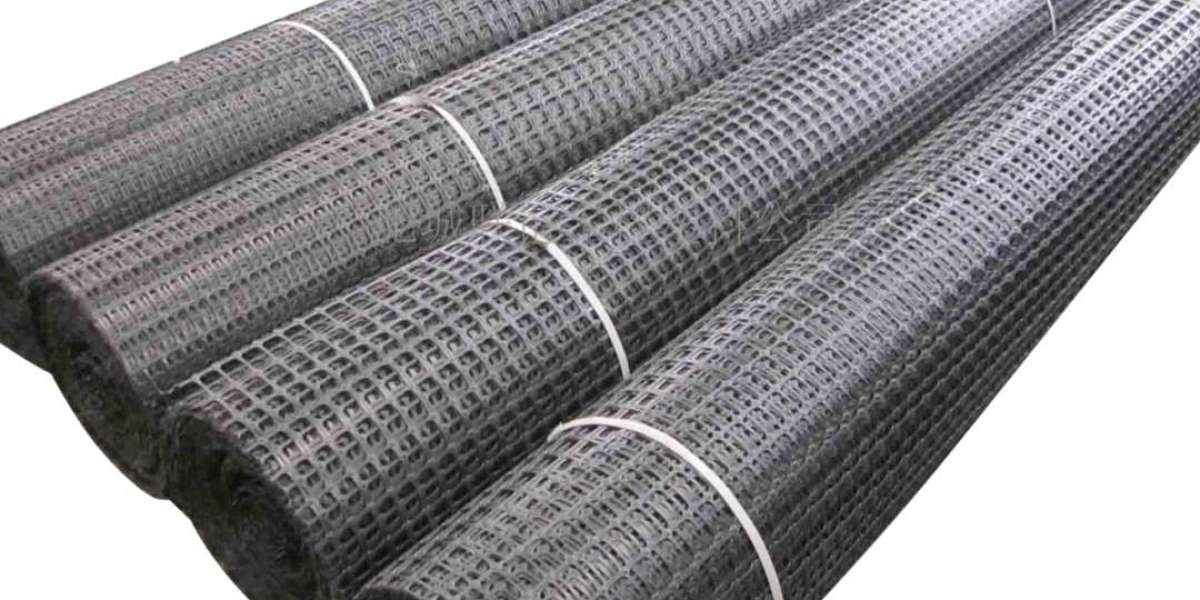

It offers excellent durability, flexibility, and high tensile strength, making it ideal for stabilizing weak soils, increasing load-bearing capacity, and preventing soil erosion. In modern infrastructure development, polyester geogrid plays a crucial role in road construction, retaining walls, and railway projects.

What is Polyester Geogrid?

Polyester geogrid is a synthetic geosynthetic material made from high-strength polyester fibers coated with PVC or another polymer for added protection. The open grid structure of the PP geogrid manufacturer in Indiaallows soil particles to interlock, providing excellent reinforcement properties. It is widely used in civil engineering, roadways, and slope stabilization projects.

Advantages of Polyester Geogrid

- High Tensile Strength: Polyester geogrid has excellent tensile strength, making it ideal for reinforcing weak soils and preventing deformation under heavy loads.

- Flexibility: Unlike rigid geosynthetic materials, polyester geogrid offers superior flexibility, allowing it to adapt to soil movement and environmental conditions.

- Durability: The high-quality polyester fibers used in geogrid manufacturing provide long-term performance, even in harsh environments.

- Resistance to Chemicals and UV Rays: Polyester geogrid resists degradation from chemicals, UV radiation, and biological factors, ensuring a longer lifespan.

- Improved Load Distribution: It helps distribute loads evenly across the soil, reducing settlement and enhancing the stability of structures.

- Cost-Effective: The use of PP geogrid supplier in Ahmedabadreduces construction costs by minimizing excavation, material usage, and maintenance.

Applications of Polyester Geogrid

- Road Construction: Polyester geogrid strengthens road foundations by reinforcing the subgrade, reducing rutting, and increasing the lifespan of roads.

- Retaining Walls: Used in retaining wall structures to enhance stability and prevent soil displacement.

- Railway Projects: Improves the load-bearing capacity of railway tracks, reducing maintenance costs and ensuring long-term stability.

- Slope and Embankment Stabilization: Provides reinforcement to slopes, preventing landslides and erosion in hilly terrains.

- Landfill and Pavement Reinforcement: Enhances the structural integrity of landfills and pavements, ensuring better load distribution.

Choosing the Right Polyester Geogrid

When selecting a polyester geogrid for a project, several factors must be considered:

- Tensile Strength: Depending on the project requirements, choose a geogrid with adequate tensile strength.

- Aperture Size: The grid's aperture size should allow for proper soil interlocking and drainage.

- Coating Type: The type of polymer coating used can affect durability and resistance to environmental factors.

- Project-Specific Requirements: Different applications may require specific geogrid properties; consulting a PP geogrid manufacturer in India can help in selecting the right product.

Leading PP Geogrid Manufacturers and Suppliers in India

India has several reputed manufacturers and suppliers of polyester and polypropylene (PP) geogrids, ensuring quality and affordability. If you are looking for a PP geogrid supplier in Ahmedabad or a PP geogrid manufacturer in Gujarat, many established companies offer customized geosynthetic solutions for construction and infrastructure projects.

Installation of Polyester Geogrid

Proper installation is essential for achieving the best results with polyester geogrid. The installation process involves:

- Site Preparation: Clearing the installation area and removing debris to ensure a stable foundation.

- Laying the Geogrid: Unrolling the geogrid carefully over the prepared surface, aligning it with the project design specifications.

- Anchoring: Securing the geogrid using pins or stakes to prevent movement during construction.

- Overlapping and Jointing: If multiple geogrid sheets are required, ensuring proper overlapping to maintain structural integrity.

- Covering with Soil or Aggregate: Backfilling with soil, gravel, or other materials to integrate the geogrid with the surrounding ground.

Conclusion

Polyester geogrid is a highly durable and flexible soil reinforcement solution used in various construction applications. Its superior tensile strength, resistance to environmental factors, and cost-effectiveness make it a preferred choice for engineers and contractors. With the growing demand for infrastructure development in India, the need for high-quality geogrids is increasing. If you require a reliable PP geogrid manufacturer in Gujarator a PP geogrid supplier in Ahmedabad, many reputed companies provide tailored solutions to meet project requirements.

Frequently Asked Questions (FAQs)

1. What is the difference between polyester geogrid and polypropylene (PP) geogrid?

Polyester geogrid is made from high-strength polyester fibers and is coated for added durability, whereas polypropylene (PP) geogrid is made from polypropylene materials. Polyester geogrids generally offer better flexibility and tensile strength, making them ideal for reinforcement in demanding applications.

2. Can polyester geogrid be used in wet conditions?

Yes, polyester geogrid is designed to withstand moisture and wet conditions. However, proper installation and drainage considerations are necessary to ensure optimal performance in such environments.

3. How do I determine the right type of polyester geogrid for my project?

The selection of polyester geogrid depends on project requirements such as soil type, load conditions, and environmental factors. Consulting with a trusted PP geogrid manufacturer in India can help in choosing the best geogrid for your application.