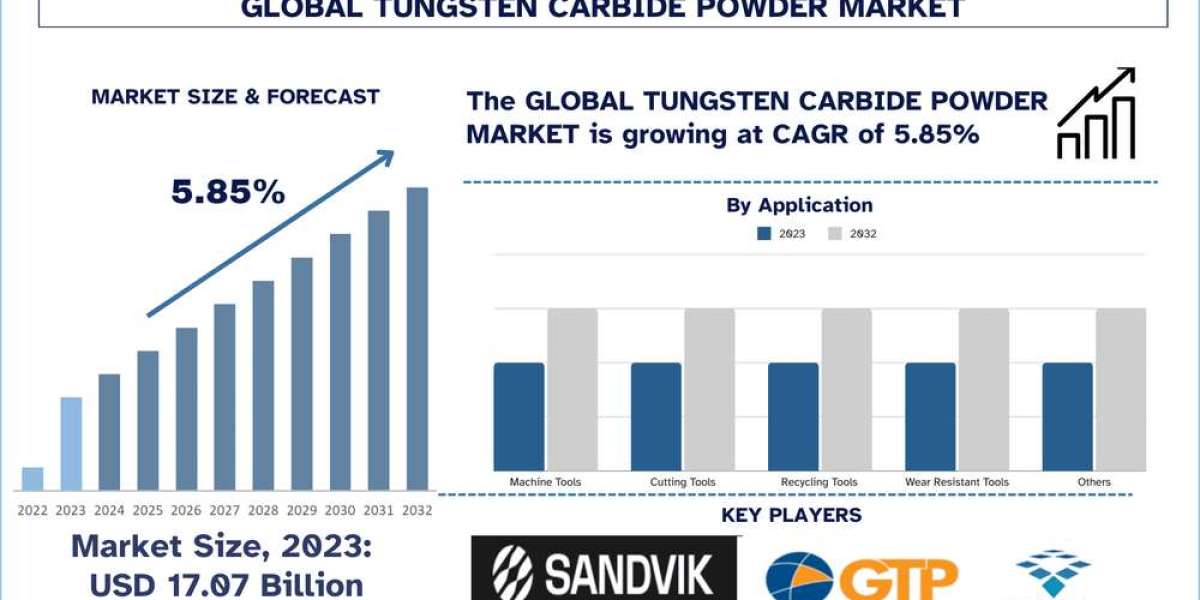

According to a new report by UnivDatos, the Tungsten Carbide Powder Market is expected to reach USD 28.58 billion in 2032 by growing at a CAGR of 5.85%. Tungsten carbide powder is one of the important material powders with high hardness and wear resistance. It is greatly utilized in manufacturing cutter and drilling tools, mining machinery and wear-resistant products. The market has started to recover slowly since the beginning of the year 2021 which has boosted by the increase in industrialization and infrastructure construction around the globe.

Request To Download Sample of This Strategic Report – https://univdatos.com/reports/tungsten-carbide-powder-market?popup=report-enquiry

KEY GROWTH DRIVERS:

There is increase in demand from metal working industries, extended mining operations and increased infrastructural development projects. Tungsten carbide because of its high hardness and wear resistance, has no substitute in many industrial uses. The automotive and the aerospace industries are also one of the biggest consumers of high-performance cutting tools and wear-resistant components. For instance, as National Mining Association published in its report, 2020, the United States mined 535.4 million short tons of coal, in 2023, it mined reached 577.5 million short tons.

Latest Developments

· In September 2024, Kennametal Inc. announced the expansion of its comprehensive product line of tooling and wear protection solutions for mining applications. The new additions include picks to meet diverse customer demands as well as an innovative round drill steel system designed to improve efficiency and safety. The company has launched three products called PrimePoint, PlusPoint, and Defender™Round Drill Steel System.

· In April 2022, Sandvik expanded its additive manufacturing capabilities by introducing 3D-printed components made from cemented carbide. This advancement is achieved through a patented process and in-house production of specialized powder. Cemented carbide, known for its exceptional hardness, is commonly used in wear-resistant parts across various industries.

· In March 2022, Element Six (E6), part of the De Beers Group, has announced the introduction of a new, state-of-the-art, fully automated line for road milling bit manufacturing, expected to be in service in the second quarter of 2022. The multi-million-dollar investment will significantly expand E6’s capacity for the manufacture of wear-resistant tungsten carbide tools and enable the company to service its customers more efficiently thanks to faster production speeds at its Burghaun, Germany, facility.

Tungsten Carbide Powder Market Fuels Soaring Growth Across Diverse Manufacturing Sectors

The manufacturing sector across diverse end users has shown significant market share and is expected to retain the largest market share throughout the forecast period. This dominance is attributable to the fact that most applications of metal cutting, forming, and machining today incorporate tungsten carbide tools. Automotive and aerospace industries act as the primary clients for these cutting tools because those industries are sensitive to precision cutting tools.

There is already a shift toward auto manufacturing and high-speed machining, to name a few, therefore boosting the call for first rate tungsten carbide tools. For example, BMW Group reported an increase in their tooling consumption for their new electric vehicle production lines, with tungsten carbide tools making up 70% of their cutting tool inventory.

Small and medium-sized manufacturers are rapidly adopting tungsten carbide tools to improve productivity and reduce machining costs. Additionally, with the growing government support of various countries in the world to make their manufacturing industry strong, there is an upscale in the demand for the powder. Likewise, India supported the local manufacturers by “Make in India” and “Vocal for Local” initiative which has boosted the manufacturing sector, consequently rising the tungsten carbide powder market.

Click here to view the Report Description & TOC - https://univdatos.com/reports/tungsten-carbide-powder-market

Browse Related Reports:

. Abrasives Market: Current Analysis and Forecast (2021-2027)

. Powder Coating Equipment Market: Current Analysis and Forecast (2022-2028)

Conclusion

The global market for tungsten carbide powder is expected to indicate significant growth in the future due to the growing number of applications across industries and development in technology. The ecological mindset and the utilization of the recycling concept are changing the tendency of the industry, plus, new areas of application set generous opportunities in additive manufacturing. Since manufacturing activities are projected to increase in the future globally, the same market will continue to require tungsten carbide powders widely, especially in developing nations where industrialization is gradually advancing.